Henry Ford faced a business dilemma in 1914. Public opinion was that he was eccentric, crazy, an outsider. The cost of his Model T was around $500, but the per-capita income in the United States was only $354 in 1913. Additionally, factory workers were very nomadic, travelling from factory to factory to obtain higher wages. Its business was at risk and employee turnover was also creating supply chain constrains.

His solution was controversial, yet pragmatic: he increased the daily wage for his workers to $5.00 from $2.38, and slashed an hour off his employees’ workday, from 9 to 8. His thinking was that if he wanted the motorcar to be widely accepted by typical Americans, he needed to pay his workers enough that they could afford to use the products they worked on all day. Turns out, it worked. By 1916, profits doubled, and sales grew immensely. By 1921, Ford had control of half of the U.S. auto market and the price of a Model T was about half of per-capita income.

By deciding based on necessity but flavoured by creativity, he achieved a rebound from his current circumstance. He:

(1) solidified his labour force

(2) drastically increased profit

(3) changed the perception the public held of him. He played a long game instead of being short-sighted

Present-day companies are facing a dilemma of their own. For the vast majority, the Coronavirus crisis has brought with it much supply chain disruption. To overcome this disruption, companies should learn from Henry Ford’s pragmatism. His approach may provide companies with a blueprint to prepare for a post-COVID reality. As Ford did, they should think with ‘creative practicality’ and use supply chain improvement as a vehicle to elevate their post-crisis standing. Here are six recommendations on how to do so:

PLAN FOR THE REBOUND

When restrictions loosen, there will be a large rebound in demand for goods and services. Companies that can adapt to the changing economic climate more quickly than others should be able to secure a larger portion of that demand. From a supply chain standpoint, this can be achieved by proactively solidifying relationships with their most strategic suppliers. After a time of extended decline in sales and inactivity, suppliers should be willing and able to help their customers optimize their supply relationship. Pricing should reflect that willingness to help. As well, opening lines of communication with those key supply partners will give insight into their inner workings. Visibility into inventory levels, production capabilities, and changing lead times will make supply chain decision making more efficient and effective.

EXAMINE YOUR SUPPLY CHAIN’S EFFECT ON PRICING

As business slowly trends towards ‘normal’, pricing will become an integral aspect of a company’s recovery plan. Looking into the supply chain’s effect on pricing will drive great benefit. Post-crisis supply costs – logistics costs, material costs, warehousing costs – will be volatile as uncertainty grips the economy. That volatility can be tamed by strengthening relationships with providers, and by keeping a consistent eye on market trends.

LOOK AT DEGLOBALISATION

If the coronavirus has taught us one thing with steely certainty, it’s that global supply chains are fraught with fragility. As demand reverts to pre-COVID levels, companies are examining their past choice to ‘globalize’ their supply chains because it has hampered their ability to adapt quickly in this crisis. As a recent article in the MIT Sloan Management Review stated:

“Companies, lulled by efficient and relatively inexpensive logistics and transport, have been applying lean and just-in-time production methods that span global networks. The current crisis exposes the vulnerability of this approach.” (Willy Shih)

Though the per-unit purchase cost of a good may be higher after the regionalization of supply, having a quickly adaptable supply chain is a benefit that should not be ignored. Noteworthy risks are emanating from regions that fuel many of today’s supply chains, so localizing as much of a company’s supply base as is feasible has become a worthwhile move.

INNOVATE (NOW)

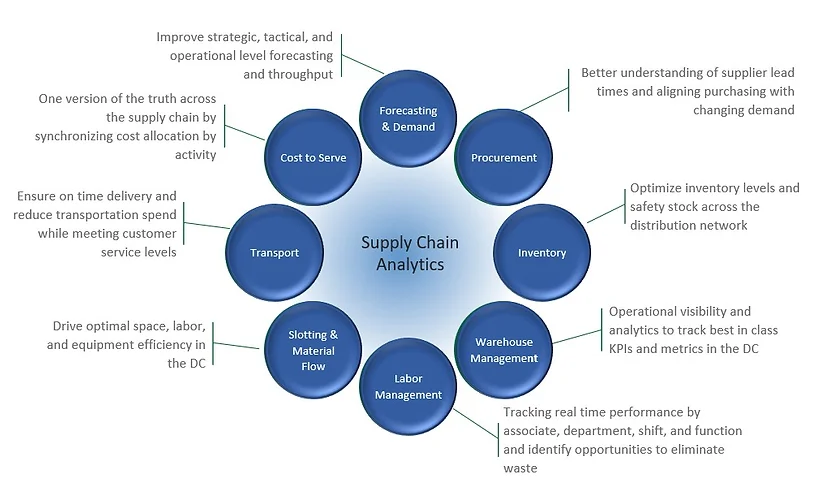

Positioning a supply chain as a strategic entity allows a company to achieve true supply chain optimization. By aligning supply chain improvements with the overall business plan, the “why” becomes obvious. The “how” should include supply chain innovation if a company wants to distinguish itself from its competitors. Innovative methods and technologies can take operational information that’s unseen and/or unused and turn it into actionable supply chain insights. Companies will need to use supply chain data analytics (see below) to drive effective decision making. This will be extremely vital as companies attempt to unearth efficiencies to give them an advantage in their industry.

Figure 1 – Areas of Supply Chain Analytics (Source: www.agillitics.com)

PREPARE FOR A BOOM IN E-COMMERCE

Supply chains need to take a shift in sales approach into account. This health crisis has brought with it a defined increase in online shopping. Everything from pet food and groceries to health-related items has seen a spike in online demand. As this continues, inventory strategies and policies should be re-examined to ensure enough allocation to online channels, and a limitation of excess inventory for other channels. Demand for last-mile delivery service capacity will also contribute to the challenges a supply chain will face as consumer interest shifts from traditional sales methods to more online demand.

EMBRACE “TEAMING”

This latest health crisis has caused companies to embrace “teaming”, a term popularized by Harvard professor Dr. Amy Edmondson, where people come together quickly (and often, temporarily) to solve new, urgent, or unusual problems. Companies should rapidly apply this concept to their supply chain strategy. By bringing members of their supply chains closer together – even temporarily – and giving them clear, concise goals to strive for, supply chains will move faster and be more agile. This will lead to a previously unseen ability to handle the unique challenges a post-crisis reality will hold.

Nothing will fully prepare supply chains for what lies ahead of us. This kind of disruption hasn’t been encountered previously. How expedient a company is in mobilizing the Henry Ford thinkers in their supply chain will gauge how well-equipped they will be to succeed in a post-crisis economy.