Episode I:Raw materials lead time and the “workaround” economy

Companies, both large and small, invest in software programs to automate, simplify, and facilitate standard practices within their supply chains. Successful implementations require extra focus on ‘scrubbing’ the data used to set the initial system parameters because, as we all know, “garbage in equals garbage out.”

Often, data cleansing is a manual process which consumes significant resources and time. It is also a critical step, one that will determine the success or failure of a software implementation. Even after a successful software implementation, issues can appear in the complex web of supply chain processes.

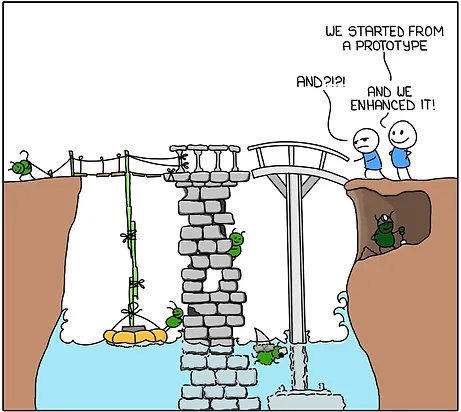

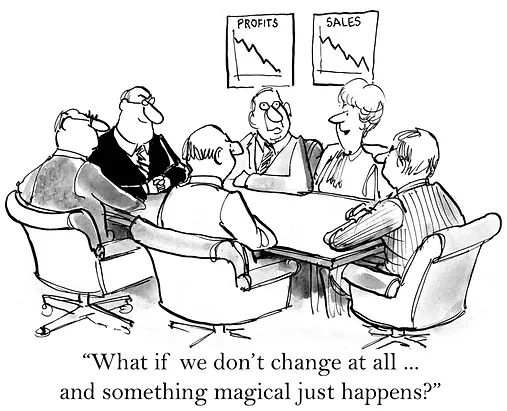

Raw materials don’t arrive on time. Last minute changes to production schedules become more frequent. Customer orders are not shipped in full or are delayed. Employees tend to create manual workarounds to address the gaps caused by (what they assume is) “the system not working.” Many of these workarounds become standard practice, sometimes so ingrained that new employees are taught to ignore and manually override system prompts. More often than not, the problem resides not with the “system” but with the parameters within which the software works. On-going master data auditing and maintenance of system parameters is as important as the initial set-up yet this maintenance is rarely a priority.

Take for example a mid-size consumer packaged goods company with whom we recently worked. This company deals with hundreds of suppliers, both local and international, to procure the thousands of raw materials they require to produce more than 1,000 finished goods. They implemented an ERP system ten years ago however, recently, both production planning and delivery to customers have been unreliable. Planners consistently bypassed the system because they lacked trust in the MRP prompts. The company had a few theories but had not been able to clearly define the root causes of the production and fulfillment issues. Time and resource constraints were barriers to turning their existing data into actionable information.

This CPG company looked to The Owl Solutions for assistance. In a matter of days, the team from The Owl Solutions was able to install their Owl Supply Chain Performance platform, extract the necessary data from the company’s existing ERP, and provide them with a dashboard of standard supply chain performance metrics reports. The Procurement Dashboard clearly identified a significant gap between the ERP lead time parameters and each vendor’s actual demonstrated lead time. These gaps were driving inconsistent signals to the MRP planning bench and, to compensate for the inconsistency, planners were creating and maintaining offline spreadsheets and manually overriding system prompts. The company frequently paid extra to expedite raw material deliveries from suppliers.

Leveraging their new data-driven insights, the company opened productive, fact-based, performance discussions with their suppliers. Lead time parameters were updated in their systems, the planning bench provided more accurate prompts, planners’ confidence in MRP accuracy grew, and manual spreadsheets were eliminated.

Employee efficiency and effectiveness increased with the improved data visibility and analytics. Within a few months of using Owl, the company not only reduced expedited freight costs for inbound materials but also improved outbound delivery and order fulfillment to their retail customers.

Operational efficiency and cost reductions, collaborative and productive partner discussions, and improved customer service and satisfaction are just some of the benefits that can be achieved by combining data with business intelligence. Owl’s Supply Chain Performance Platform can help you mine the data in your existing ERP or transactional system and turn it into clear, understandable business metrics that can drive better, more informed business decisions.

Improve your supply chain today by speaking to one of our experts.